Our Salute Board: Part 2 - Planning

This is the second part of my journal on the preparation of our boards for Salute 2014.We are running a Caesarian Roman game at Salute 2014 with Simon Miller (aka the BigRed Bat).Now that the materials have started arriving, the real work begins!

The board

When planning the design of the board I had several factors to take into consideration. I had a general idea of how I wanted it to look but that would inevitably change when the materials arrived. The basic plan would now have to become the plan actual! Let me explain: plans usually never quite match with reality. There are always hidden obstacles or unexpected difficulties, which cause plans to be changed. Such is the nature of projects, both big and small.

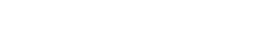

We followed Simon’s map (which appears in WSS 72) as a rough guide. Plans were drawn and discussed. The sea would be very important, so we needed at least 18” of “sea” to allow all of our ships on. I opted for six 2ftx3ft boards plus a sea shore of three sections of 1ftx4ft (these were small enough to fit on the back seat if needed).

The materials

As explained before, the ideal board size for transportation is 2ftx3ft. While Styrofoam is very resistant, I decided to put plyboard on the back to give it extra rigidity just in case. Craftfoam is very resilient, I can stand of a piece and the surface will hardly have any impression. I opted for 25mm thick Craftfoam in 120mmx60mm lengths.

Even with Craftfoam, there was a risk of a board snapping if enough pressure was put on it, particularly (as I had planned) we were going to carve rivers into it. I opted for 3mm plyboard – on polystyrene this would be disastrous as the board would just bend as the glue dried, bending the Polystyrene with it. However Craftfoam is made of sturdier stuff and my test board didn’t bend at all. Perfect! I had a lightweight and transportable yet durable board.

Gluing

I opted for PVA glue, choosing to glue both sides of the surfaces, as both the plyboard and Craftfoam absorbed the PVA very well. Drying time might be an issue, but I kept them in a warm area that speeded things up considerably. Weighing down the boards was essential, so they’d stick evenly over all surfaces. So I dug out every book and spare weight I could find to weigh them down. The books helped distribute the weight over a larger area.

My friend Ian Crouch recommended Craftfoam to me. He uses a hot glue gun and 9mm MDF board. The glue will adhere the foam to the board very well and quickly (unlike PVA). 9mm MDF is a good thickness to use – it is about the minimum thickness of board, which should have no warping, is not too heavy and thus portable.

Next time I’ll discuss making and shaping the board.